|

|||

|

|

|

||

| View Shopping Cart |

| Home |

| Guides Available |

| About the Author |

| FAQs |

| Testimonials |

| Articles |

| Contact Andrew |

| Terms & Conditions |

| Mailing List |

| Links |

|

|

Get more high quality electric modeling information, absolutely free:

Sign up for the Gibbs Guides newsletter now!

Electric Flight Glossary

& discussion of electric flight terms

Part 3 - L to P

by Andrew Gibbs

There are many technical terms and words relating to model

aircraft in general, and electric flight in particular.

The aim of this detailed glossary is therefore to offer

an accurate and detailed yet concise explanation for any

of the terms the electric modeller is likely to come across.

Let us know if a term you'd like to see covered is not

discussed here!

LiPo/Li-Poly/Lithium battery

This is a modern type of battery and it is in almost

universal use for flying models. The nominal voltage

is 3.7 Volts per cell (Vpc). The absolute maximum

safe battery voltage is 4.2 Volts per cell, and the

minimum cell voltage before serious damage results

is 3.0 Volts per cell, under no load conditions.

LiPo batteries are light in weight, are capable of delivering a high current and are able to store relatively large amounts of energy. As a result, the combination of LiPo batteries and brushless motors have transformed electric flight. However, the disadvantages of this battery type are that they are relatively fragile and can burst into flames if abused, damaged in a crash or over charged. LiPo batteries are an excellent source of power for model aircraft provided they are used properly.

LiPo batteries are examined in more detail in this Gibbs Guide.

Li-Ion/Lithium Ion

This is another type of lithium-based cell, but these

are rarely used these days for electric power models.

Maximum charged voltage is 4.1 Volts per cell. They

have a hard case, and are therefore are physically

more durable than LiPo cells. They are also more resistant

to electrical abuse such as overcharging. However,

they are heavier than LiPo types, and do not have

such a high capacity for a given weight.

Lithium

Polymer (LiPo) batteries have transformed electric

flight in recent years. |

LiPo

batteries can catch fire if overcharged, as

seen here. (Photo courtesy of

Simon Sheldon) |

LVC (Low Voltage

Cut - Off)

This is another name given to the PCO function.

See the entry for 'Power Cut Off'.

mAh

The term mAh is an abbreviation for milli-Amp-hour,

which is used in battery terminology as unit of measurement

of battery capacity. 1,000 mAh equals 1 Amp hour.

For example a fully charged 3,000 mAh battery can

supply 3,000 mA (the same as 3 Amps) for one hour

before it is exhausted.

Motor losses

A well designed electric motor can achieve an impressive

efficiency. However, no electric motor is 100% efficient

as there will inevitably be losses of energy within

the motor. There are four causes of lost energy within

an electric motor, which are termed copper loss, iron

loss, air losses and friction losses. Each of these

losses is detailed separately within this glossary.

Nickel Cadmium (Nicad) cells

Nicad cells have a nominal voltage of 1.2 Volts per

cell. Compared to LiPo cells, nicads are heavy, and

have low capacity for a given weight. However they

are extremely durable. For many years nicads were

the only practical cell for use with electric power

aircraft and were in widespread use both as flight

packs and for RC power. However, because of the toxicity

of cadmium, nicad cells are no longer available. However,

due to their durability there are still a substantial

number of nicad packs in use in modeling applications,

especially for RC system power supply. For reasons

of safety, all batteries in safety critical applications

such as for RC system power supply duty should be

regularly inspected and tested before use.

Nicad

batteries are unfortunately no longer available

for modeling use. This is a pity as they were

more durable than hydrides, and had much to recommend

them. |

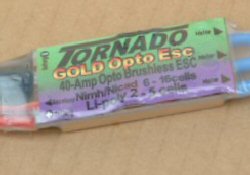

Opto

isolating ESCs cannot offer a BEC function. Models

equipped with opto isolating ESCs therefore need

a separate power supply for the RC system. |

NOS

The abbreviation is sometimes found in modeling discussions.

It simply stands for New Old Stock i.e. an unused, but

old item.

Opto isolator

Electric motors and ESCs inevitable generate an amount

of electrical noise. Because all the components of the

power system and the RC system are linked, there is

a tendency for this noise to be fed to the receiver,

compromising its performance.

To combat this problem, some ESCs use an opto isolator chip. Although the ESC is still connected to the receiver, the opto isolator feature allows the receiver to be electrically isolated form the ESC. Instead, the communication between the receiver and ESC is accomplished optically, using pulses of light in the manner of a fibre optic cable. This feature greatly reduces the amount of electrical noise which reaches the receiver.

Because there is no direct electrical connection between

the ESC and the receiver, the ESC cannot supply power

to the RC using a BEC function. The RC system must therefore

be supplied by a separate battery dedicated to RC system

power.

The

brushless outrunner motor is very popular for

electric power model aircraft. |

All

ESCs have a PCO function. This cuts power to the

motor at an appropriate point to prevent the battery

from becoming excessively discharged. |

Outrunner Motors

The outrunner motor is a design of brushless motor in

which the magnets are fixed to a rotating outer case.

The windings are located at the centre of the motor,

arranged around an inner (fixed) former. The magnets

run outside of these windings, hence the name of this

motor type. The propeller driver is attached to the

rotating outer case.

Outrunners have a relatively large diameter, and this characteristic naturally gives them a high torque, making them suitable to drive relatively large diameter, efficient props. This is the principal reason they are the usual choice for the majority of electric RC sport and scale models, as well as indoor 3D models and park fliers.

You can find a lot more information about brushless motors in the guide Mastering Motors, available here

PCO (Power Cut - Off)

PCO is the abbreviation given to the Power Cut Off function

of an ESC. The PCO detects when the battery voltage

falls to a user-defined threshold, and initiates a reduction

or shut down of power to the motor to prevent the battery

from falling to an unacceptably low voltage. If this

were permitted, the battery may become damaged and/or,

when RC system power is derived from the flight battery

via a BEC, control of the model could be lost.

Permanent Magnets

The permanent magnets used in brushed and brushless

motors have varying degrees of magnetic strength and

temperature resistance. Ferrite magnets are weakest,

while Samarium Cobalt and Neodymium types are substantially

stronger. Permanent magnets generally lose magnetic

strength as they are heated, but recover as they cool

down again. However, there is a temperature beyond which

the magnet will suffer a permanent loss of its magnetism.

Partially de magnetized motors cause the motor to draw significantly more current and generate more heat accompanied by a reduced power output. For these reasons, care must be taken not to allow electric motors to become excessively hot in use. In all cases, it is worth remembering that the outside of the motor case will be a lot cooler than the magnets inside, so a good rule of thumb is to make sure that the outside of the motor does not exceed 80-100C. The temperature of motors and other components can easily be measured after flight by means of a simple, cheap infra red thermometer.

Pitch

The pitch of a propeller is the forward distance the

prop will move, if there is no resistance to movement.

For example, a prop with a 6 inch pitch will theoretically

move forward 6 inches in one revolution.

Pitch to diameter ratio (p/d ratio)

The pitch to diameter ratio of a propeller is simply

the ratio of the prop’s pitch to its diameter.

For example, to find the p/d ratio a prop with a 12

inch diameter and a 6 inch pitch (12 x 6) the calculation

would be: p/d = pitch/diameter = 6/12 = 0.5. A 12 x

6 prop therefore has a pitch to diameter ratio of 0.5.

Similarly, a 10 x 8 has a p/d ratio of 0.8, a 8 x 6

has a ratio of 0.75 and so on.

The p/d ratio is of important significance when matching a prop to a model. Fast models should have props with a high p/d ratio e.g. 10 x 8, while slow models are best off with a much lower ratio, for example a 10 x 5.

Pitch speed

The pitch speed of a propeller is the speed it would

travel forwards if there was no resistance to its movement,

in other words, if no model was attached to it. The

pitch speed is found by multiplying the prop pitch by

the rpm:

Pitch speed = Prop pitch x Prop RPM

Pitch speed gives a useful indication of how well suited a particular power system is to a particular airframe. The pitch speed will always be higher than the airspeed of the model.

You can find a lot more information about props in the guide More Than Motors, available here

Power (Watts)

Power is a measure of the rate at which work is done.

Power can be either mechanical or electrical. Mechanical

power is usually measured in horsepower. The definition

of mechanical power is Power (hp) = Torque x RPM.

Electrical power is measured in Watts, or for larger amounts of power the kilowatt. A 0.40 capacity model engine typically develops about 1 hp, which is equivalent to 746W.

The power of an electric model aircraft is found by multiplying the voltage and the current:

Power (Watts) = Voltage x Current (Amps)

Propeller

The propeller, or prop for short converts the rotational

energy provided by the motor into thrust. The rotating

prop unavoidably also imparts a slight swirling motion

to the airflow. Larger props are more efficient than

smaller ones, and small increases in propeller diameter

can yield a relatively large increase in efficiency.

Prop driver

A prop driver is a device fitted to the output shaft

of a motor which is designed to allow easy attachment

of the propeller.

Prop drivers for outdoor models are usually of the collet type. These work well, giving a secure, solid fit. Occasionally a set screw type will be encountered, but these are best avoided. The prop driver must be correctly sized for the motor shaft diameter in question. Common motor shaft diameters are: 1.5mm, 2mm, 3mm, 3.17mm (1/8?), 3.2mm, 5mm and 6mm.

Prop saver

Low powered indoor models sometimes use a different

type of prop adapter, called a prop saver. These consist

of a metal adapter, designed to allow the prop to be

held on with a rubber band. This arrangement, which

is only suitable for very low power models, gives the

prop an increased measure of crash resistance.

Pusher prop

A pusher prop is one which is located behind the motor

driving it. The prop is said to push the model, rather

than pulling it as in a tractor installation. In spite

of this terminology, reality the propeller works in

exactly the same way regardless of whether it is in

a tractor or pusher configuration.

Click here for the next part of the glossary