|

|||

|

|

|

||

| View Shopping Cart |

| Home |

| Guides Available |

| About the Author |

| FAQs |

| Testimonials |

| Articles |

| Contact Andrew |

| Terms & Conditions |

| Mailing List |

| Links |

|

|

Gibbs Guides.com

More high

quality information absolutely

free with every

Gibbs Guides newsletter.

Sign

up now!

Propeller problems!

By Andrew Gibbs

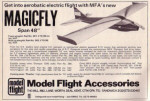

No

photograph survives

of the Magicfly I

built, but I did find

this 1978 advert for

the kit. The design

utilised a really

thick (14.5%), flat

bottomed wing section

with strip ailerons

and tip plates. The

model was available

in foam and built-up

balsa wing variants. |

The first electric RC model I ever built was the Magicfly, by Model Flight Accessories (MFA). This was in the really early days of electric powered RC flight, around 1979, while I still a schoolboy. A discussion of the difficulties I experienced still has some relevance to today’s electric models.

This 48 inch span foam winged model was powered by a geared 540 motor (a sort of early 600 motor), 8 x 1200mAh NiCad cells, a 12x4 Kiel Kraft plastic prop of dubious efficiency and nothing more sophisticated for motor control than a servo-operated on/off microswitch. The model was successful in that it did fly, but was disappointingly lacking in performance, usually having only just enough thrust to be capable of flight. I remember that it was more or less a ‘one speed’ model; unless it was flown at precisely the correct airspeed, (set by the elevator) it simply would notclimb. This experience proved to be useful many years later when I flew a full sized FRED homebuilt, powered by an old VW Beetle engine, which had a similar, alarmingly poor rate of climb!

Taxiing

out for my one and

only flight in this

underpowered F.R.E.D. |

Returning to the Magicfly, I don’t remember how long the motor would run for, but this was irrelevant because I was forced to land well before the batteries were exhausted simply because the model could only sustain flight with well charged batteries!

Fairoaks

airport, 1993. Being

briefed by the owner

of the F.R.E.D. The

initials stand for

Flying Runabout Experimental

Design, the aircraft

was designed by Eric

Clutton, an aeromodeller

of some repute, now

living in the USA.

The wing’s pronounced

undercamber can be

seen very clearly. |

At that time electric modeling really was a ‘black art’, with very little information around to help the newcomer. Although there was the odd magazine article, I never found that these answered my many questions. I think it was the troubles I experienced with this model fuelled a desire to thoroughly understand and explain the technicalities of electric flight, a passion which lasts to this day.

Many years later on, it’s now clear to me why this model was lacking in performance. For success with an electric power model, especially when using brushed motors such as the old 540 the Magicfly used, there needs to be enough power, plus each element of the entire power system needs to operate at a reasonable level of efficiency to ensure the available power is not unnecessarily wasted. Thus the motor, propeller and battery all need to be considered. Let’s look at each of these factors in turn:

An

old 540 motor and

gearbox, similar to

the unit installed

in the Magicfly. The

yellow prop is a Keil

Kraft 12 x 4. Alongside

it is a modern electric

prop. |

Available

Power

The Magicfly weighed around

3lbs (1,360g), and I estimate

that its 540 motor would

have consumed around 15Amps.

Today, it’s generally

accepted that 50 Watts per

pound is sufficient for

this type of model, though

it’s fair to say that

some 25 years ago our performance

expectations were lower,

so 40 watts per pound would

probably have been considered

just about enough.

A motor drawing 15A at 8V (the likely on-load voltage for an early 8 cell pack of nicads) has an input power of 120 watts. (15x8 = 120) This indeed equates to 40 watts per pound, and so the model probably did have sufficient power - its problem was therefore more likely to do with how efficiently that power was used.

Propeller

I remember that judging

by the way the model pulled

at full throttle, the Magicfly

seemed to have an impressive

static thrust (the thrust

at zero airspeed), and I

was mystified as to why

it had so little airborne

performance. Interestingly,

looking through some old

back issues, I read that

an RCM&E reviewer also

found the model was a somewhat

marginal performer, so I

was not alone. However,

he at least was using the

recommended prop!

In fact, I had not understood the importance of the propeller factors that need to be considered with electric power models. Perhaps the three most important of these are pitch speed and dynamic thrust (the thrust at flying speed) and pitch to diameter ratio. (These themes are explored in more detail in the article ‘A few words about propellers’ – add this sentence when the prop article is added)

Static

& dynamic thrust

Static thrust is often measured

by modelers; it’s

an easy measurement to make,

requiring little more than

a simple spring balance,

and seems at first sight

to be a useful indicator

of flying performance. However,

static thrust is only really

of relevance at zero airspeed;

the only such situations

I can think of are

a) At the first instant

of take off

b) During prop hanging maneuvers

c) The rotor of a helicopter

in hovering flight

|

|

| It is static thrust keeping these models airborne. The extraordinary scale FW61 helicopter was designed and built by the remarkably skilled Dutch modeller Appie Van Moorst, and was seen at an electric meet in Holland in 2004. The equally extraordinary large prop hanging electric model has 12 kilowatts of power on tap. Ian Watson of FlightTech is the talented pilot. | |

All of these are zero airspeed situations. However, as soon as a model is moving, it is dynamic thrust that counts. Unfortunately, for the average modeller without access to specialized equipment such as a wind tunnel, dynamic thrust is impossible to measure.

So what can we do? Well, the usual method is to avoid tackling the question of dynamic thrust head-on. Instead, we simply ensure that sufficient power is installed in the model and trust that with a suitable propeller installed that the resulting dynamic thrust will be sufficient.

One of the factors by which we can assess whether of not a prop is suitable is its pitch speed. For the average model, this method tends to work very well. After this, it’s a matter of experimenting with different props to find the best match for the particular combination of motor, model and the required flying style.

Pitch

speed

Propeller pitch is defined

as the distance that a prop

will try to move forward

in one revolution - for

example, a prop with a 6

inch pitch will try to move

forward 6 inches with each

revolution. To help visualize

this, we can liken the prop

to a screw thread, which,

with each turn, tries to

pull itself forward as it

is rotated.

If we also know the rotational speed of the prop, then we can say with some confidence what the forward speed of the propeller will try to be – this is known as the pitch speed. It can be seen that pitch speed is affected by only two factors: pitch and rpm.

Pitch speed is therefore defined as the speed at which a propeller will try to move forward as it rotates, if no resistance to its forward motion exists. In practice, some resistance will exist, and is caused by the aerodynamic drag of a model. This drag will cause some ‘slippage’, so the actual distance the model will move forward with each revolution of the prop will normally be less than the pitch speed. If it helps getting to grips with the idea, pitch speed can also be thought of as the speed at which air will be ‘thrown back’ by the prop.

The table below shows the pitch speed resulting from various combinations of prop rpm and prop pitch. For example, it shows that a prop with a pitch of 8 inches rotating at 5,000rpm will give a pitch speed of about 38mph.

Pitch

speed of various props

at selected rpm. |

||||

| Prop pitch | 4000rpm | 5000rpm | 6000rpm | 7000rpm |

| 4 inches | 15mph | 19mph | 23mph | 27mph |

| 5 inches | 19mph | 24mph | 28mph | 33mph |

| 6 inches | 23mph | 28mph | 34mph | 40mph |

| 7 inches | 27mph | 33mph | 40mph | 46mph |

| 8 inches | 30mph | 38mph | 45mph | 53mph |

Although the figures in the table have been carefully calculated, notice that a fair approximation of pitch speed can be made simply by multiplying prop pitch in inches by rpm in thousands – for example 8 inches x 5,000rpm = approximately 8 x 5 = 40 mph. This is very close to the table speed of 38mph, and quite accurate enough for most purposes.

A poor

choice of prop

From memory, I recall that

the plan called for an 11x6

prop. Knowing very little

about such matters, I had

instead fitted the model

with an old plastic 12x4

from my spares box, which

was meant for internal combustion

(i.c.) models. I used it

simply because modeling

funds were tight and to

my inexperienced eye it

looked close enough in size.

At that time, I didn’t

really understand about

propeller pitch so I didn’t

give this issue much thought.

However, it’s now

clear that this prop was

a bad choice because the

4 inches of pitch was far

too low, resulting in too

low a pitch speed.

Being meant for an i.c. model, this sturdy nylon prop was also relatively heavy. Furthermore, the blade shape of this i.c. prop was probably rather inefficient for the low rotational speeds offered by the geared ferrite electric motor. However, in those days suitable lightweight electric props were simply not available.

Choice

of pitch

Let’s now look at

the pitch speed issue in

more detail. The 540 motor

I used probably achieved

about 15,000rpm on its freshly

charged 8-cell pack. The

gearbox used had a 3:1 ratio,

so this meant that the prop

speed was probably around

5,000 rpm, giving a pitch

speed of about 19 mph (from

the table). Since some slippage

is inevitable, the maximum

possible flying speed would

have been at best a few

mph less, perhaps 16mph,

a slow speed indeed.

This slow pitch speed almost certainly corresponded closely to the minimum possible flying speed of the model. Additionally, it was probably also close to the minimum drag speed of the model. The propeller provided just enough dynamic thrust to keep it airborne at this one speed. This explains why the model had been a ‘one speed’ device – if it was flown at a higher or lower speed than this, drag exceeded thrust and it descended. Tricky indeed!

Pitch

to diameter ratio

All else being equal (which

is rarely the case in aeromodelling)

props with low pitch to

diameter ratios are considered

to be inefficient, and that

generally, those with a

ratio of less than 0.5 are

best avoided. That old 12x4

was down around 0.33 (4/12

= p/d ratio 0.33) so its

efficiency was probably

very poor.

I did try a number of other props without success, but due to ignorance of the cause of the problem, these did not include an 11x6 or 12x6 – had I done so, things might have worked out a lot better on all counts - the pitch speed would have been closer to about 30mph, the pitch/diameter ratio would have been more efficient at about 0.5 (6/12 = p/d ratio 0.5) and also I’d have had more power from the motor due to the higher load. Unfortunately I hadn’t realized that I was so close to success, and so I sold the model on. I hope its new owner had a better selection of props than I did!